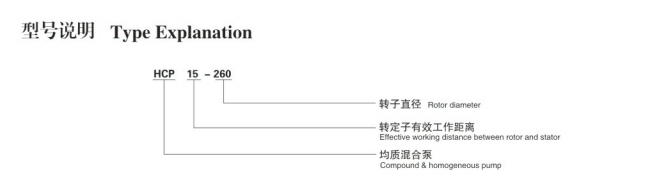

Introduction to homogenizing emulsification pumps/homogenizing mixing pumps

Hollysys HEP1, HEP3, HDP, HCP, HHP emulsification pump series enjoys a certain market rate in the world, homogenization emulsification pump and homogeneous mixing pump is the company according to the actual application conditions of the domestic combined with international advanced technology research and development of multi-purpose hybrid emulsification equipment, the manufacturing technology and processing accuracy of the product to reach the high-end level of similar international products. Homogenization emulsification pump is a kind of high-efficiency equipment integrating emulsification, homogenization, dispersion, mixing, crushing, fine, dissolving and depolymerization. The main working parts are composed of pump cavity, rotating stator and bearing seat. The rapid operation of the rotor takes the animal material to form centrifugal force and cooperate with the stator, and the material is quickly sheared, impact crushed, centrifugally dispersed, liquid layer mixed, turbulent uniform and other comprehensive effects, so that the solid phase, liquid phase, gas phase and other media in the material are uniformly emulsified and finely dispersed in an instant, so that the product can reach the ideal particle diameter and distribution form, and form a stable and high-quality product. This series of products further simplifies the original traditional production process, greatly improves production efficiency and product quality. This series of products are widely used in food industry, biopharmaceutical, daily chemical, fine chemical, pesticide fertilizer, environmental protection, papermaking, ink coating and other industries. In the food industry such as soy protein, food grade sauce, saccharified powder, salad dressing, ketchup, pet feed, cakes and bread. Hollysys homogenization emulsification pump is characterized by high purity of materials, and to achieve a good mixing and homogenization effect, and the failure rate is low, the enterprise is simple to use, improve employee awareness, reduce costs for enterprises, save time, and get the attention and preference of high-end pet feed manufacturers.

Application areas

Food industry, biopharmaceutical, daily chemical, fine chemical, environmental protection, papermaking, ink coating, pesticide fertilizer, etc.