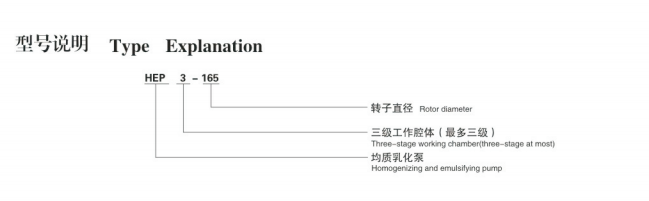

Product introduction:

There are three groups of rotors and stators in the working cavity of HEp3 homogeneous emulsion pump. Each rotor has two layers of toothed discs. There are 12 layers of toothed discs in the three groups of rotor stators. The clearance between the rotor and stator teeth from the inlet to the outlet is from thick to thin. Under the same specifications, HEp3 can provide better emulsification effect and larger processing capacity per unit time than hep1. When HEp3 works, the materials are dispersed, refined and emulsified step by step through the three-stage rotor and stator, which greatly improves the production efficiency. It is a high-efficiency ultra-fine homogenization pump integrating mixing, dispersion, crushing, dissolution, refinement, depolymerization, homogenization, emulsification and transportation. The product further simplifies the traditional production process and significantly improves the product quality, It is an ideal product instead of colloid mill.

The product is suitable for large and medium batch continuous on-line production or circular production process.