Petrochemical Industry

Based on our experience serving domestic and overseas petroleum enterprises, the materials transported are almost all flammable liquids, with stringent requirements for safety, temperature, and pressure conditions, necessitating suppliers to utilize higher-grade or the highest-grade manufacturing. In the engineering cases we have served, Hollysys' stainless steel rotor pumps, rubber rotor pumps, and homogenizing emulsifying pumps have been in contact with materials such as crude oil transportation, tanker unloading, oil depot cleaning, condensed oil transportation, polyacrylamide, residual oil, wax oil, asphalt oil, oily wastewater, and other liquids, gases, and solid mixtures requiring transportation. There are also process requirements for mixing and homogenization. The pump materials (flow passage materials) and precision manufacturing requirements such as shaft seals, mechanical seals, sealing, and no leakage are strictly examined and reviewed. When the materials contain particles, acids, strong acids, flammables, or explosives, the flow passage components are required to be corrosion-resistant and wear-resistant, and explosion-proof motors (provided by specified enterprises) are used. When the outdoor pump temperature is below 20°C, the pump is required to be low-temperature resistant with a long service life. Daily inspections, annual inspections, and major inspections are conducted on the pump's operating cycle as part of the after-sales service. The pump's design, manufacturing, and inspection should comply with normative standards. Additionally, the self-priming issue has been effectively resolved by Helsh-Tech rubber rotor pumps, which also address corrosion, wear, and stainless steel lining wear issues.

Engineering Cases

Condensed Oil Rotor Pump

Based on the characteristics of condensed oil, Helsh-Tech rotor pumps are specifically designed and developed for this material's operating conditions, matching the on-site process flow and technical transportation requirements. The material is similar to gasoline, containing hydrogen sulfide and gases. It solves issues such as preventing dry running and dry burning during production, which could damage the rotor, ensuring normal operation of pressure changes generated during material operation without dry burning. Moreover, Helsh-Tech technical engineering department has effectively addressed technical supplies such as maintaining a fixed flow rate at low pressure and increasing pressure at the same flow rate, gaining unanimous recognition from enterprise technicians.

Surfactant Rotor Pump for Heavy Alkyl Benzene Sulfate in Oil Displacement

In oil displacement surfactants, advanced sulfur trioxide is used as a sulfonating agent, which has been industrially applied. During transportation, the rotor pump needs to overcome increased viscosity due to reaction temperature. Helsh-Tech rotor pump replaces other pump types, effectively preventing leaks and other issues arising during transportation. The material has high viscosity, strong corrosion, and contains particles. Helsh-Tech rotor pump has undergone special design for this type of material, with special (specified) materials used for the flow passage components and mechanical seals (specified by the buyer) to ensure corrosion and wear resistance. Equipped with safety settings, it avoids safety hazards due to excessively high pressure during production. Product features include low noise, low speed, smooth and safe operation, effectively improving production efficiency and reducing maintenance costs.

Viscous Oil Rotor Pump

Among the media served by Helsh-Tech rotor pumps, such as heavy oil, residual oil, finished fuel oil, crude oil, and heavy crude oil, these media are commonly characterized by high viscosity and poor fluidity. Ordinary pumps cannot be customized like rotor pumps according to different material viscosity concentrations. Helsh-Tech rotor pumps effectively overcome technical faults by combining flow rate and pressure. In market applications, Helsh-Tech rotor pumps have replaced traditional pump types for transportation based on advanced scientific theory combined with practice, shortening maintenance time, reducing excessive cost consumption, wear resistance, and product life. With refined manufacturing technology and a professional service team, Helsh-Tech specializes in product functionality, featuring high performance, low speed, small size, strong self-priming capability, bidirectional operation, convenient use and maintenance, energy efficiency, durability, etc. It has achieved good results in fields such as crude oil extraction, petroleum refining, and refined oil transportation.

Oil Recovery Additives and Oily Wastewater Rubber Rotor Pump

The oil recovery additives in contact with Helsh-Tech rotor pumps are polymer dispersants or molecular flocculants specifically used in oil extraction, water treatment, and papermaking. Polyacrylamide is used as a filter reducer, flocculant, diluent, and plugging agent in oil extraction. Based on the characteristics of this material, Helsh-Tech rotor pumps have replaced traditional pumps in the field of oil extraction, solving issues such as ease of damage and reduction in maintenance costs and energy conservation. Helsh-Tech rotor pumps have been procured by oil extraction enterprises. The rotor is wrapped with special wear-resistant rubber and molded in one process, featuring strong self-priming capability and no shedding during use. It solves the transportation over long head distances and reduces wear on the rotor caused by small impurities in oily wastewater, reducing maintenance costs for enterprises. It improves efficiency and is reliable and convenient for self-priming in oily wastewater ponds, sewage self-priming, and storage tank self-priming. When equipped with a frequency converter, it can control and adjust the flow rate.

Multi-Tube Mixing and Emulsifying Pump

The main purpose of the multi-tube mixer is to mix materials. It transports different types of raw materials into the pump chamber according to proportional requirements and instantly mixes, homogenizes, disperses, crushes, fines, dissolves, etc. It is widely used for mixing and homogenizing multiple materials and for neutralization reactions in chemical process flows. It has become the core equipment for continuous online production, simplifying the original production process and integrating it into a highly efficient piece of equipment.

Self-Priming Rotor Pump

The clearance between the rotors is designed and customized according to the viscosity of the material. A certain clearance is maintained between the rotor and the pump body, and sealing relies entirely on the material reaction to form its own essence. The chamber needs to be filled with material for the first use, and when the equipment is restarted, it achieves self-priming without the need for refilling.

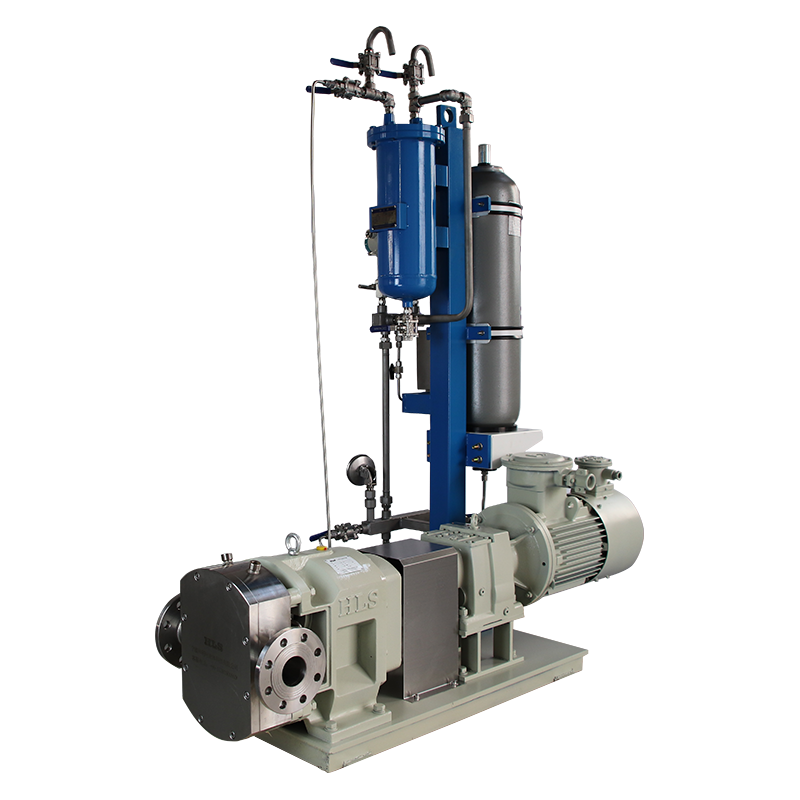

Safe Volumetric Transfer Pump

Volumetric rotor pumps are equipped with safety devices based on the characteristics of the transported medium and operating conditions, serving as an important means of protecting the pump and preventing damage due to misoperation, thereby increasing the pump's service life.

Insulated Transfer Rotor Pump

This product is equipped with an insulation device designed to prevent temperature changes when the material flows from the reaction vessel to the pipeline. It helps prevent pump wear caused by the solidification of the material on the mechanical seal's dynamic and static rings. When operating viscous materials, it facilitates startup and operation without jamming the pump or damaging the mechanical seal due to unstable temperature changes, suitable for use in conditions where the viscosity of special materials is greatly affected by temperature.