Product Category

FGS Rubber Rotor Pump

Item No.:

HLS-G002

Category:

Summary

TEL:

TEL/Whatsapp/Wechat:

E-mail.:

Product Detail

- Description

- Performance

- Parameters

-

- Commodity name: FGS Rubber Rotor Pump

- Commodity ID: HLS-G002

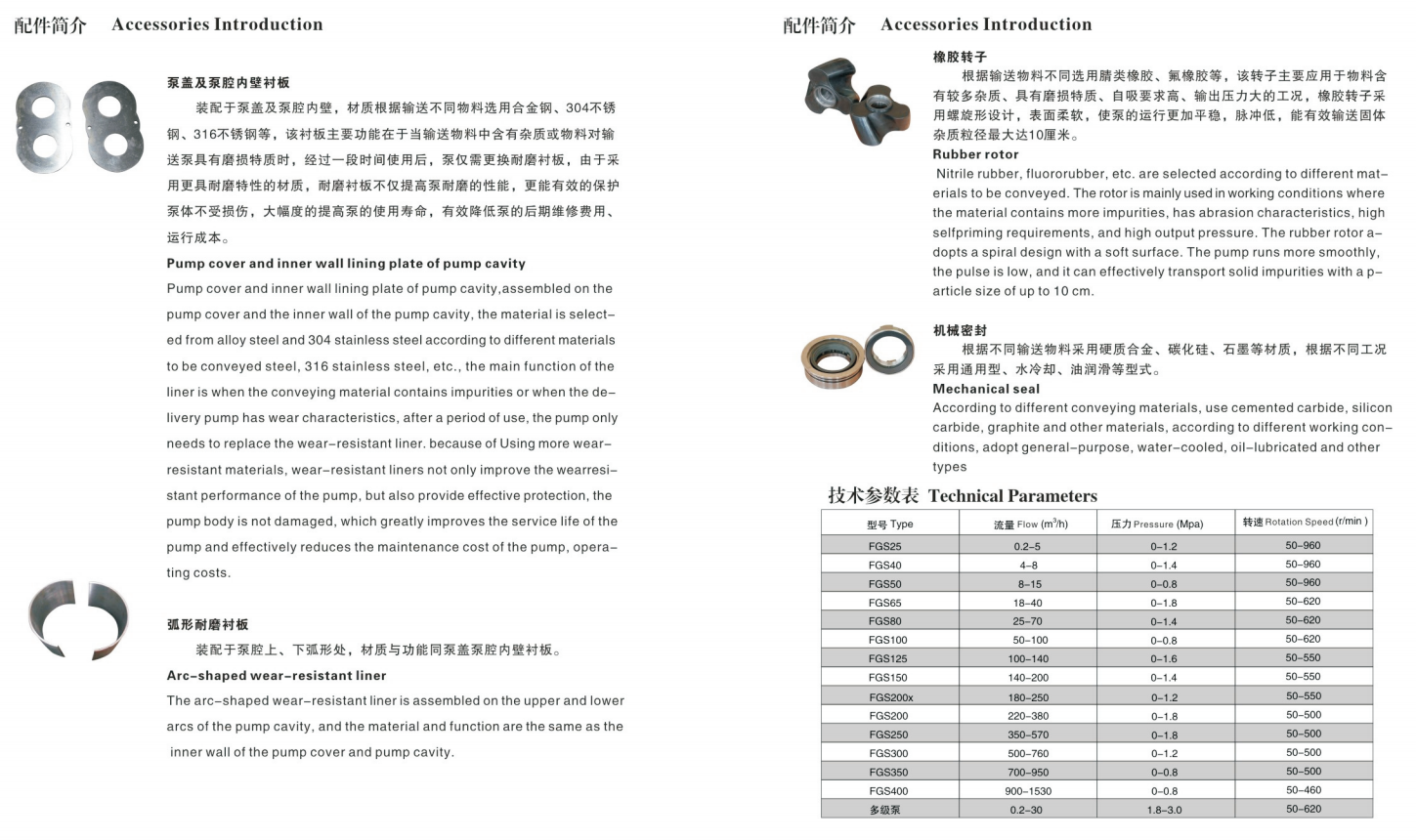

The built-in wear-resistant lining plate in the pump cavity can effectively protect the pump cavity from wear, prolong the service life of the pump and reduce the later use cost. It can be maintained online, and the parts can be checked or replaced by opening the pump cover.

Product features:

The built-in wear-resistant lining plate in the pump cavity can effectively protect the pump cavity from wear, prolong the service life of the pump and reduce the later use cost. It can be maintained online, and the parts can be checked or replaced by opening the pump cover. There is no need to lift the equipment and remove the pump from the pipeline. It is convenient for maintenance and saves a lot of maintenance time. The spiral rotor runs smoothly with stable pressure and flow. Compact structure, small floor area, easy to install and transport pipeline routing. It can realize the mixed transportation of gas, liquid and solid. Such as massive materials, fibers, hair, etc., will not block. The pump can rotate forward and backward, the inlet and outlet can be interchanged, and the two functions of loading and unloading can be realized at the same time. It can transport medium with viscosity ≤ 2 million CP. It has strong self-priming ability, and the suction range can reach 8.5 meters. Independent seal cavity design, keep the seal face lubrication, idle for 15 minutes will not produce any damage to the pump. The rotor and pump body can be made of corresponding materials according to different conveying conditions.

Application fields:Environmental protection: municipal sewage, chemical wastewater, lime slurry, precipitated sludge, thickened sludge, etc.

Petrochemical Industry: heavy oil, heavy oil, source oil, fuel oil, lubricating oil, asphalt, sludge, oil, catalyst, multicomponent oil, etc.

Papermaking: polyacrylic size, sizing solution, rosin size, paper, coating, amine emulsion, defoamer, filter aid, water treatment chemicals, etc.

Food: dairy products, fruit juice, puree, concentrated juice, cream, syrup, chocolate, ice cream, condensed milk, condiment, distiller's grains, soybean protein, mushroom powder, etc.

Daily chemical products: AES, MES, AOS, Las, K12, glycerin, fatty alcohol, detergent, facial cleanser, shower gel, shampoo, toothpaste, soap, detergent slurry, etc.

Fine chemicals: dyes, pigments, sodium, adhesives, silicone oil, leather oil, emulsion explosives, etc.

Chemical fiber: glass fiber, viscose paste, PVA, vinylon size, refined fiber size, spandex size, polymer chip, man-made fiber, etc.

Pharmaceutical: ointment, extract, medicine emulsion, pill paste, medicament and so on. Coating: paint, paint, ink, resin, additives, organic solvents, etc.

Fire fighting: foam pump and fire pump.

-

1、 Stainless steel rotor pump wholesale excellent sealing, as a must rotor pump machinery and equipment company, to choose a better rotor pump to carry out the work, first look at its sealing condition. In general, the requirements of machinery and equipment are relatively high, and the design schemes of many manufacturers are relatively high-precision, so it is not easy to have all the water leakage, which is convenient for the working process. 2、 Swing rotor pump has strong self-priming ability in wholesale, followed by the application effect of strong self-priming ability of rotor pump, which can give full play to a very strong role and replace some commodities with less effect. The self-priming ability can reach the middle of 8.5-9.5 meters, which can be said to be very able to meet the requirements of using personnel. Such a rotor pump will not have frequent product quality problems, and has the advantages of composition. The centrifugal impeller and its hydropower control design scheme are selected, and the whole process is smooth. 3、 The rotor pump is easy to operate and maintain. When it comes to the application effect of the rotor pump, no matter how good the effect is, daily equipment maintenance and management must be carried out. Because the rotor pump is used for a long time, it is very easy to cause certain damage if the maintenance is not carried out on time. Therefore, in the case of operation, according to reliable instructions to operate, to prevent equipment damage.

-

MAIN PRODUCTS

EXPLORE OUR PRODUCT LINEUP

Rotary Lobe Pump

The rotary Lobe Pump is a kind of positive displacement pump. There is a pair of synchronous counter rotating cams in the pump cavity. Hollysys fluid technology has always been committed to combining the product with practical application, continuously upgrading and improving the product.

Learn More +

Rotary Lobe Pump

The rotary Lobe Pump is a kind of positive displacement pump. There is a pair of synchronous counter rotating cams in the pump cavity. Hollysys fluid technology has always been committed to combining the product with practical application, continuously upgrading and improving the product.

Learn More +

Rotary Lobe Pump

The rotary Lobe Pump is a kind of positive displacement pump. There is a pair of synchronous counter rotating cams in the pump cavity. Hollysys fluid technology has always been committed to combining the product with practical application, continuously upgrading and improving the product.

Learn More +

Rotary Lobe Pump

The rotary Lobe Pump is a kind of positive displacement pump. There is a pair of synchronous counter rotating cams in the pump cavity. Hollysys fluid technology has always been committed to combining the product with practical application, continuously upgrading and improving the product.

Learn More +