Product Category

Rotary Lobe Pump

Item No.:

HLS_07

Category:

Summary

TEL:

TEL/Whatsapp/Wechat:

E-mail.:

Product Detail

- Description

- Performance

- Parameters

-

- Commodity name: Rotary Lobe Pump

- Commodity ID: HLS_07

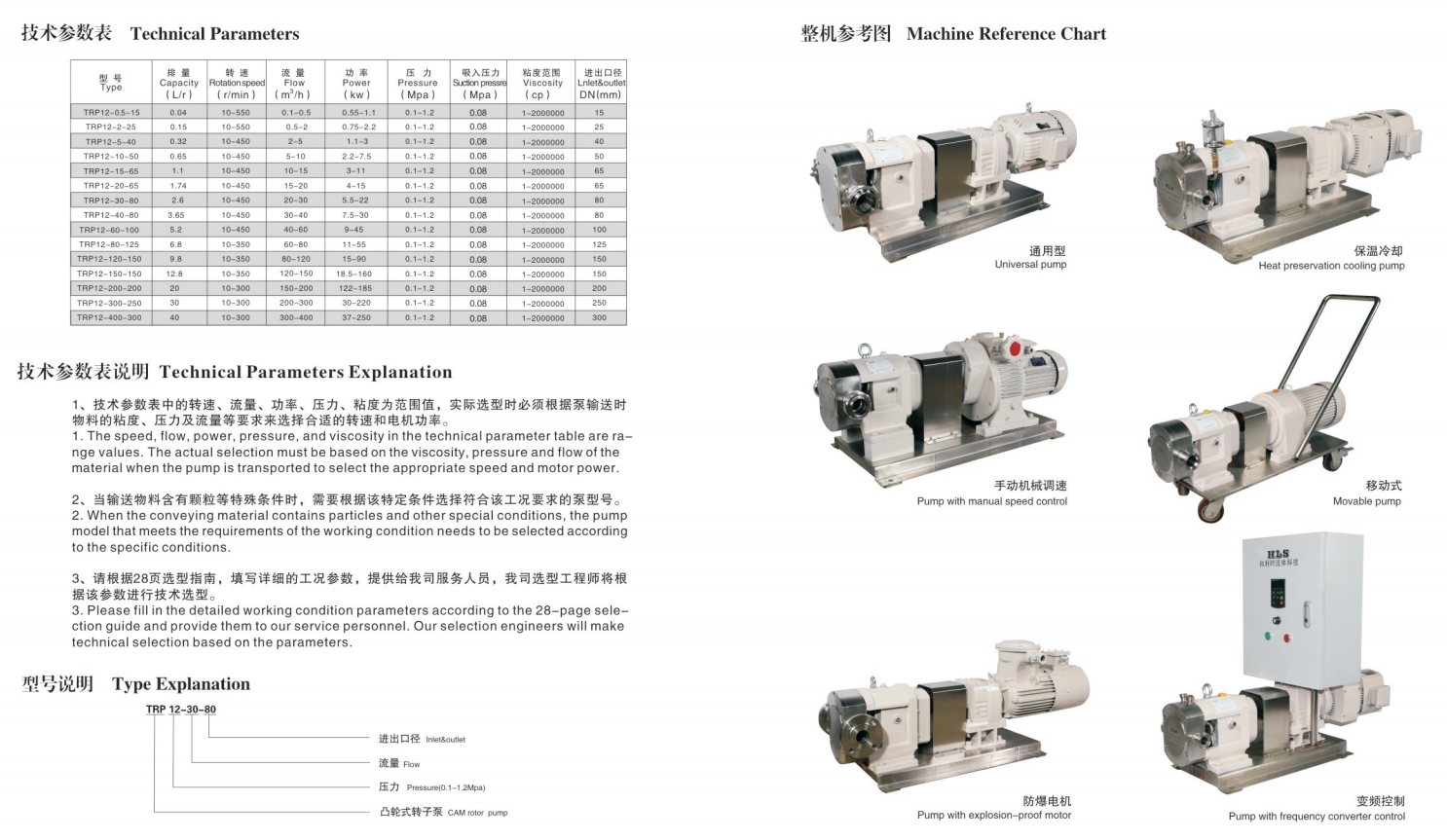

The rotary Lobe Pump is a kind of positive displacement pump. There is a pair of synchronous counter rotating cams in the pump cavity. Hollysys fluid technology has always been committed to combining the product with practical application, continuously upgrading and improving the product.

Product introduction:

The rotary Lobe Pump is a kind of positive displacement pump. There is a pair of synchronous counter rotating cams in the pump cavity. Hollysys fluid technology has always been committed to combining the product with practical application, continuously upgrading and improving the product. According to years of research and experience accumulation, it has determined a series of rotor pumps under different working conditions: chemical type, food type, general type, etc When conveying different media, the product adopts the corresponding configuration, which makes the rotor pump play the characteristics of stability, efficiency and safety in a variety of different application conditions, and provides the majority of users with the solution of fluid transportation in line with the requirements of the actual working conditions.

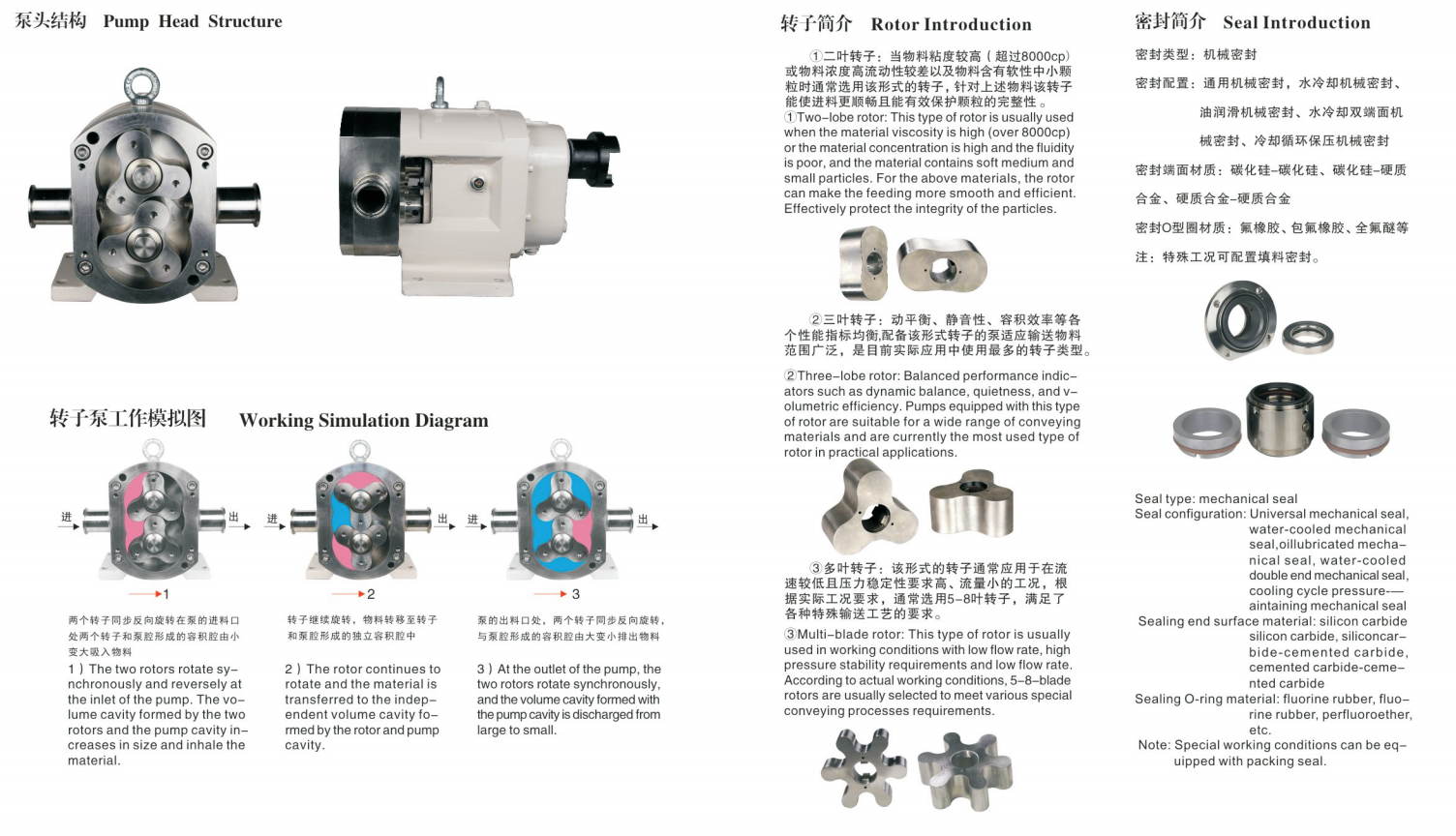

working principle:When the two rotors rotate in the opposite direction synchronously, the volume cavity periodically changes from small to large - from large to small to achieve the purpose of conveying fluid. The flow rate of the pump depends on the volume of the working chamber and its changing frequency in unit time, but (theoretically) has nothing to do with the discharge pressure; Driven by the transmission shaft, two rotors (rotor blades are 1-8) rotate in the opposite direction synchronously. In the process of rotation, the volume at the inlet increases from small to large to produce suction (vacuum degree) to absorb materials. After that, the two rotors and the pump cavity form a fixed volume cavity, and the volume at the outlet of the pump decreases from large to small to output materials, forming a higher vacuum degree and conveying pressure.

Application fields:

*Daily chemical: detergent, washing liquid, shower gel, skin care cream, shampoo, hand sanitizer, toothpaste, soap, detergent slurry, daily chemical raw materials, etc.

*Fine chemicals: dyes, pigments, adhesives, silicone oil, leather oil, chemical additives, various colloidal materials, various sizes, etc.

*Food: chocolate, condensed milk, yogurt, honey, syrup, sucrose, tomato juice, concentrated fruit juice, jam, ice cream, milk, yeast slurry, pulp, jelly, condiment, distiller's grains, soybean protein, flour slurry, etc.

*Papermaking: polyacrylamide (PAM), gelatinized starch, carboxyl styrene butadiene / styrene butadiene latex, rosin, rosin size, filler, dry strength agent, wet strength agent, sizing agent, retention and drainage aid, defoamer, coating, water treatment chemicals, etc.

*Chemical fiber: viscose pulp porridge, PVA, vinylon size, acrylic size, polyamide size, polyester chip, polypropylene, man-made fiber, functional fiber, etc.

* medicine: all kinds of ointment, extract, medicine emulsion, pill paste, syrup, health products, medicament and so on.

*Coatings: Paints, coatings, inks, insulating paints, resins, additives, organic solvents, etc.

-

Product features:

There is a certain gap between the rotor and the pump body, between the rotor and the rotor, no contact, no friction, long service life.

No need to dismantle the pipe, open the pump cover to repair, convenient maintenance and cleaning, less vulnerable parts.

Low energy loss, high efficiency, low failure rate, reliable sealing and low noise. It can transport high viscosity, high concentration, containing soft solid particles and other materials with poor fluidity.

The output flow of the pump can be changed within a certain range by adjusting the pump speed, and can be used as a general metering pump.

It can be equipped with flange type, screw type, clamp type and other types of connection, and the in and out direction can be horizontal or vertical.

It can transport gas, liquid and solid mixed materials and transport a wide range of materials. Built in thermal insulation cooling structure design, good thermal conductivity, easy installation. It can be equipped with sanitary safety valve and pump valve, and the pressure overload protection of pipeline system is simpler.

The rotor and pump cavity can transport the medium containing solid particles such as sludge and sewage after using special materials and technology.

The spherical rotor pump manufacturer is a kind of capacity pump that drives two rotors to complete the same step and reverse rotation according to a pair of gear meshing transmission system with reduction ratio of 1. During the whole rotation process, the vacuum value is created at the inlet, and then the liquid to be transported is sucked in. Generally also known as non-contact rotor pump. The basic principle is that the two rotors of the pump body are driven and rotated by two driving gears at the same step to carry out suction pipe and liquid discharge. The two rotor blades touch each other, so the available medium viscosity is very wide, from low viscosity to semi-solid and medium containing particles. The principle of the rotor pump determines the higher stability of the improved medium under high pressure, high temperature and high shear. Rotor pump has the characteristics of simple principle, small size, light weight, low cost, sealing, safety and zero pollution. It is not only suitable for hydraulic oil medium transportation, but also has potential sales market in daily chemical plants, crude oil, pharmaceutical industry, food and other fields. Therefore, the rotor pump can replace the magnetic pump and centrifugal pump in some places.

-

MAIN PRODUCTS

EXPLORE OUR PRODUCT LINEUP

Rotary Lobe Pump

The rotary Lobe Pump is a kind of positive displacement pump. There is a pair of synchronous counter rotating cams in the pump cavity. Hollysys fluid technology has always been committed to combining the product with practical application, continuously upgrading and improving the product.

Learn More +

Rotary Lobe Pump

The rotary Lobe Pump is a kind of positive displacement pump. There is a pair of synchronous counter rotating cams in the pump cavity. Hollysys fluid technology has always been committed to combining the product with practical application, continuously upgrading and improving the product.

Learn More +

Rotary Lobe Pump

The rotary Lobe Pump is a kind of positive displacement pump. There is a pair of synchronous counter rotating cams in the pump cavity. Hollysys fluid technology has always been committed to combining the product with practical application, continuously upgrading and improving the product.

Learn More +

Rotary Lobe Pump

The rotary Lobe Pump is a kind of positive displacement pump. There is a pair of synchronous counter rotating cams in the pump cavity. Hollysys fluid technology has always been committed to combining the product with practical application, continuously upgrading and improving the product.

Learn More +